Covering Embodied Carbon Series | The Climate Journal

Whole Life Carbon Assessments

Read Time 12 mins | Written by: Alex Bantock

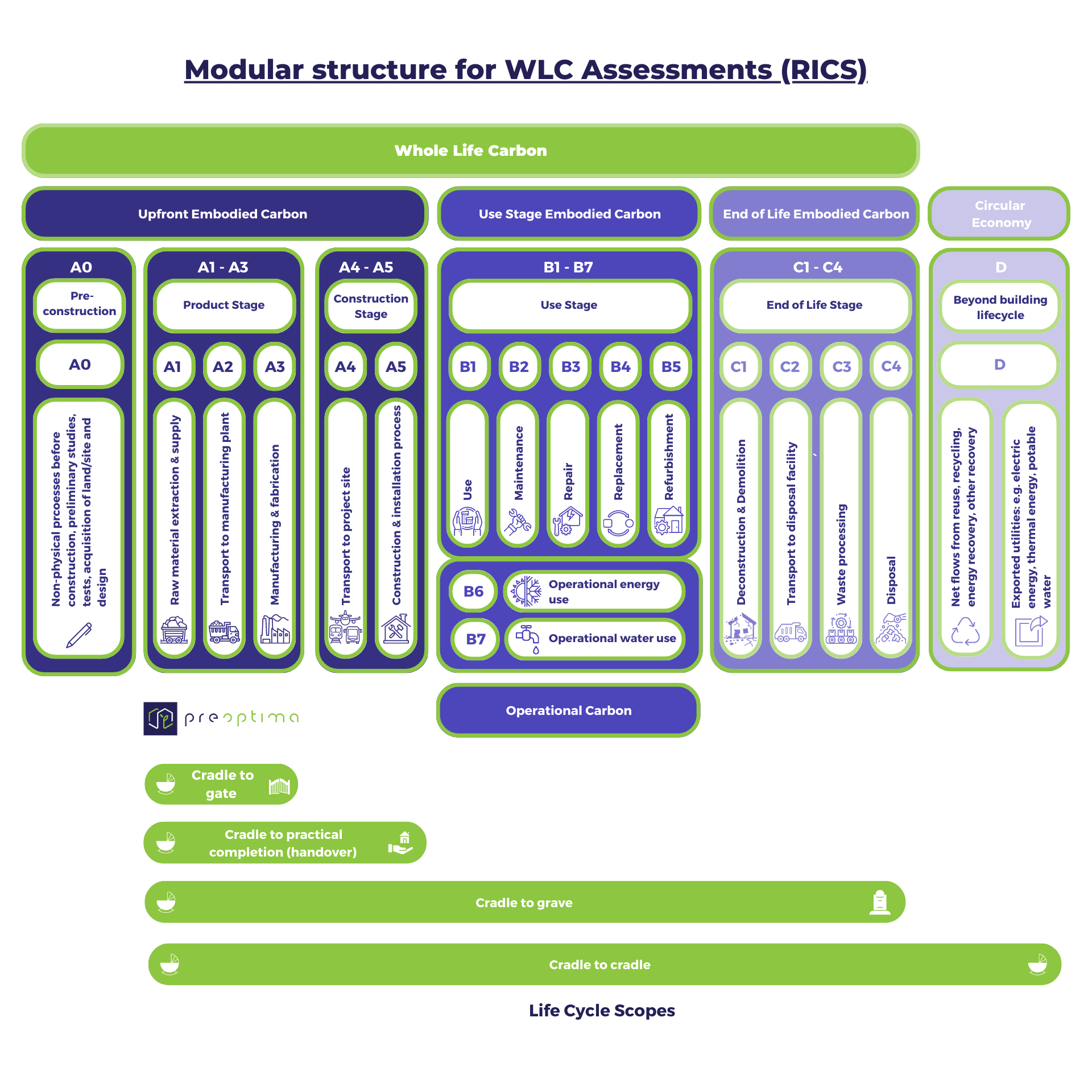

Whole Life Carbon Assessments (WLCAs) provide a comprehensive view of a building's total carbon emissions, capturing both embodied and operational emissions. The RICS guidelines offer a structured, modular approach, emphasising transparency and accuracy, to aid built environment professionals in sustainable decision-making for achieving Net Zero.

What is Whole Life Carbon?

The Whole Life Carbon of a building is the sum of the total carbon emissions* produced by the building (either directly or indirectly) over its entire life cycle. Every aspect of a building's life has an impact, including the materials used, the transport of these materials, the construction processes, the operation of a building, and its eventual demolition and disposal. Therefore, like everything, buildings have a birth-to-waste cycle and the only way that we can truly account for a building's impact is to identify and calculate the emissions produced at every stage of this cycle to create a single figure - the Whole Life Carbon (WLC).

The WLC of a building can be understood in two dimensions: embodied and operational. Embodied carbon emissions are the emissions from raw material supply, material transport, manufacturing, transport to the construction site, the construction and installation processes, and the eventual demolition and disposal of the building. Defined further, the upfront embodied carbon constitutes the emissions from the product and construction stages only, or the embodied carbon incurred prior to building occupancy. Operational carbon emissions on the other hand are associated with heating, hot water, cooling, ventilation, and lighting systems, as well as those associated with cooking, equipment, and lifts.

These two dimensions of a building are not mutually exclusive, but are in fact tightly interdependent. For example, certain choices in materials, like fossil fuel-derived insulation, can improve the operational efficiency of a building through energy savings; however, the upfront embodied carbon cost incurred by using that material can often be higher than the operational savings over its entire lifecycle - making the combined consideration of both embodied and operational carbon, through a WLC approach, crucial if we are to truly decarbonise buildings and achieve Net Zero.

Whole Life Carbon emissions are the sum total of all asset-related GHG emissions and removals, both operational and embodied over the life cycle of an asset including its disposal (Modules: A1- A5 Upfront; B1-B7 In Use; C1-C4 End of Life). Overall Whole Life Carbon asset performance includes separately reporting the potential benefit from future energy recovery, reuse, and recycling (Module D).

- Low Energy Transformation Initiative (LETI)

*One thing to note here is the frequently loose use of the term 'carbon emissions'. In WLC Assessments, 'carbon' usually refers to 'carbon dioxide equivalents' (CO2e) which is a metric used to describe, for a given mixture and amount of greenhouse gases (GHGs), the amount of CO2 that would have the same global warming ability when measured over a specified time period. Therefore, CO2e allows one to combine the global warming potential (GWP) of various GHGs into a single representative measure. See the Emissions Gap Report 2022.

RICS Whole Life Carbon Assessment for the Built Environment

The calculation of a building's WLC impact, called a Whole Life Carbon Assessment (WLCA), provides a holistic understanding of a building's environmental impact and is crucial if we are to understand and minimise the carbon emissions associated with building decisions over the entire life cycle of the building.

The International Standard EN15978 (Sustainability of construction works. Assessment of environmental performance of buildings) provides indicators, calculation rules and system boundaries for assessing the lifecycle impacts of buildings. Yet, its inconsistent application led to the creation of the first edition of the Royal Institute of Chartered Surveyors (RICS) Professional Statement, Whole Life Carbon Assessment for the Built Environment, which emphasises the implementation of EN 15978 through mandatory principles and practical guidance. RICS is currently consulting on the second edition of this standard.

The Modular Structure of WLCAs

The RICS WLC standard now forms the gold standard for how WLCAs should be performed. The requirements and guidance cover all components of a building in a modular fashion over its entire life cycle. In line with EN 15978, building parts are organised into categories and the building life cycle is divided into different modules and stages in order to address all aspects influencing WLC in a structured way.

This is less confusing when visually depicted as above, where one can see the building lifecycle divided into different modules (e.g. module A) and stages (e.g. the product stage A1-A3):

Building Modules and Lifecycle Stages

Module A covers emissions from all activities necessary to complete the construction of the asset.

- Module A0, which covers non-physical pre-construction activities, is generally assumed to be zero for buildings. However, for infrastructure projects A0 can include ground investigations and activities associated with designing the asset.

- Modules A1–A3 (product stage) cover the extraction, transporting and manufacturing processes necessary to produce the construction products, components and technical equipment required to construct the asset.

- Modules A4–A5 (construction stage) cover transporting construction products and any construction processes, up to project completion. Module A5 also includes any on-site demolition or strip-out works required at the beginning of the project.

Module B covers all emissions that occur over the use stage of the asset.

-

Module B1 reports direct emissions and removals from construction products, such as emission of blowing agents from insulation, refrigerants from MEP or removal of CO2 through carbonation of concretes.

-

Modules B2–B4 cover material-related emissions that occur from maintenance, repair and replacement of the asset.

-

Module B5 covers any refurbishment or change in performance of the asset (e.g. retrofit/refurbishment or extension) planned at the outset of the project to occur at some point after construction is completed.

-

Module B6 covers the energy use of the asset over the use stage.

-

Module B7 covers water use over the use stage.

-

Module B8 includes user activities not included elsewhere and could include, for example, emissions from vehicles using a road or the impact of commuting to an office building

For WLCA purposes, the use stage considered for modules B1–B8, also known as the reference study period (RSP), differs from country to country. In the UK, and for WLCAs compliant with this document, the RSP is taken as being 60 years for buildings and 120 years for infrastructure assets (see section 3.7 for a full explanation). Importantly, the RSP is not a limit to the life expectancy of a project; it is purely to ensure consistency of assessments across a reasonably realistic period into the future.

Module C covers emissions during the end-of-life stage of an asset.

This includes deconstruction or demolition, waste processing, recovery or disposal and associated transport.

Module D covers the benefits and loads beyond the system boundary.

-

Module D1 covers the potential carbon loads (costs) and benefits beyond the system boundary from any recovery of material arising from the construction (A4–A5), use (B2–B5) or end of life (C1–C4) stages.

-

Module D2 covers the potential carbon benefits beyond the system boundary of any utilities exported from the asset during use stages B6–B8, such as generated electricity or treated water.

Note that there is still some debate on and inconsistency with the calculation of the benefits and loads of Module D. Therefore, it is important to critically evaluate any savings derived from this module.

System Boundaries

WLCAs are further divided into system boundaries, with boundary conditions used to define what is included in the assessment, which enables flexibility in the scope of assessment without compromising consistency. The common boundary conditions include cradle to gate, cradle to practical completion, cradle to grave and cradle to cradle - where 'cradle' is used as the start for all boundaries i.e. the extraction of raw materials from the earth or the reuse/recycling of products and materials (in cradle to cradle).

A complete WLCA should account for all emissions arising over the entire life of a building, from cradle to grave (A-C). However, where more restricted scopes are determined to fit the needs of specific projects (for example cradle to gate, A1-A3 impacts), these must be identified and the life cycle stages included in the assessment clearly defined. The establishment of clear boundaries is critical for transparency and subsequent consistency and credibility of WLCA results.

Benefits of Whole Life Carbon Assessments

Increasingly, built environment professionals are commissioning WLCAs as part of their project requirements. This is primarily driven by the environmental consideration of decarbonisation, increasing regulatory pressures, and to support the built environment's efforts to achieve Net Zero. However, WLCAs have a host of additional benefits that are worth noting:

1. More accurate scope 1, 2 and 3 reporting under the GHG Protocol

2. Standardised WLCAs will provide greater consistency of results and enable meaningful comparison and benchmarking at different levels

3. Early-stage WLCAs can provide a baseline that later assessment iterations can be compared to, ensuring effective impact monitoring

4. Using credible benchmarks, relevant carbon targets and limits can be set for the WLC performance of the building to drive emissions reduction

5. WLCAs inherently foster long-term thinking, which helps to inform the future resilience of buildings and what component maintenance, repair and replacement may be required or avoided

6. WLCAs allow for the reuse, recycling and/or recovery potential of buildings and their components to be quantified, encouraging the adoption of circular economy principles

7. Better linkage with quality, easily accessible data and software tools will improve the accuracy and ease of conducting WLCAs

Key Considerations in Whole Life Carbon Assessments

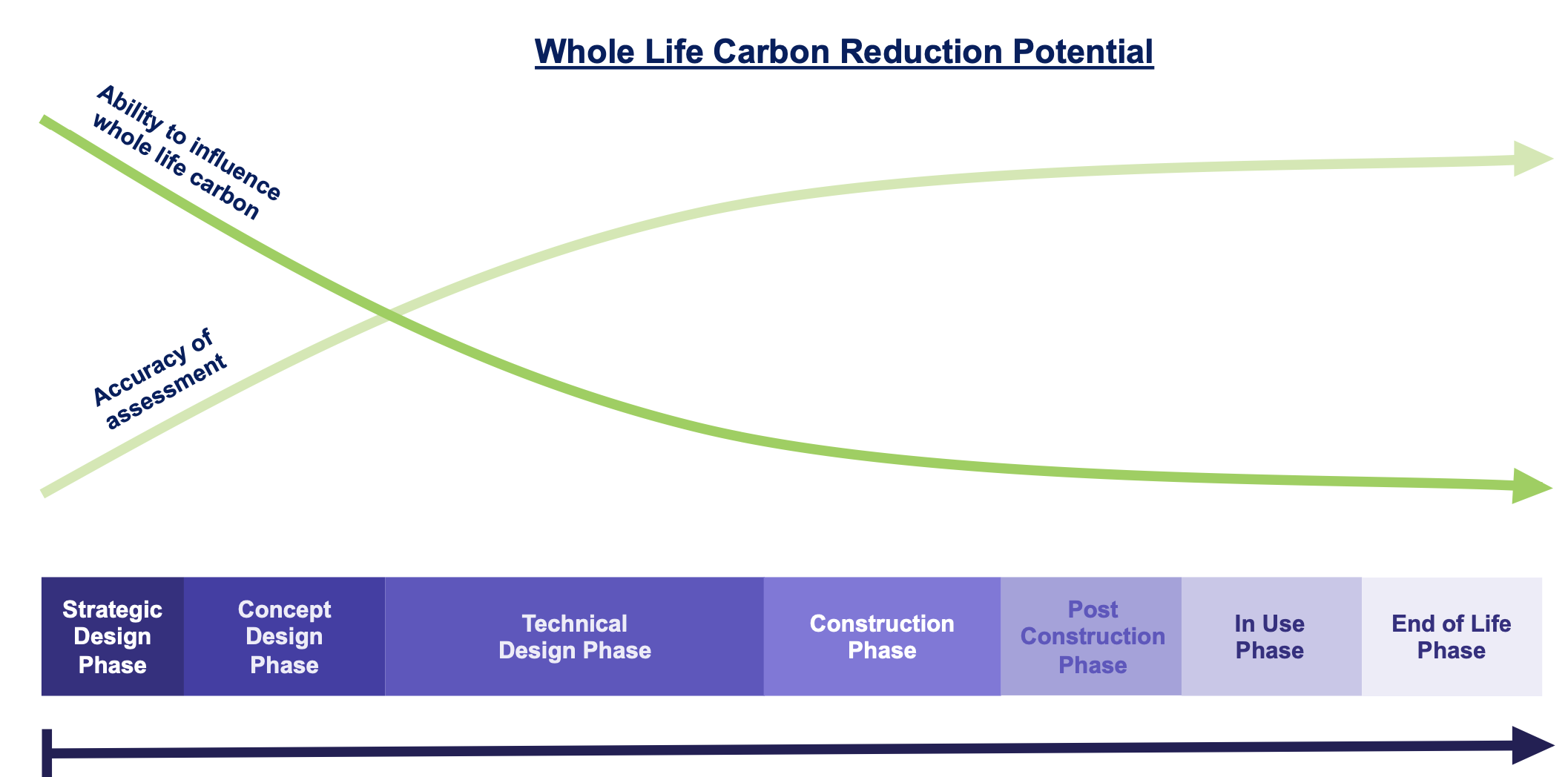

It can be said that the real value of WLCAs lies in the phase of the construction project it is conducted in. This is because one's ability to influence the WLC of a building, or its WLC reduction potential, is highest during the early design phases. As the project progresses, these carbon reduction opportunities become fewer, have reduced impact and are potentially more expensive to implement.

A WLCA can be undertaken as early as the concept design phase and is in fact recommended so that a baseline carbon emission estimate can be established and key levers for reducing the WLC of the building design can be identified when the potential to influence both the carbon and design decisions is highest.

From this point, WLCAs should be undertaken in a sequential fashion during the technical design, construction and post-completion phases of a building project to provide continuous insight into the building's carbon performance and ensure that carbon-based decision-making is factored into every stage of design.

WLCAs performed in the late design stages alone hold little-to-no benefit, as by this point significant time and resources have been invested into the design leaving little capacity for change. However, late design stage WLCAs as iterative assessments are extremely valuable in order to monitor building performance against the initial carbon emission baseline as the design develops. In addition, as-built WLCAs allow one to check that buildings have been constructed as designed and that changes have not been made during the construction process that significantly affect the carbon impact. This continuous gathering of information and the onboarding of key insights and learnings will aid stakeholders to lessen the emissions gap between as-built and as-design buildings.

According to the RICS Consultation (2023), as a minimum, a compliant WLCA should be undertaken at the following key project phases:

-

Concept design phase, e.g. pre-construction forecasts

-

Technical design phase, e.g. pre-construction and at-tender forecasts

-

Construction phase and

-

Post-completion phase, e.g. post completion assessment.

Any compliant WLCA must also comply with all relevant requirements for that project phase:

-

For the early design phase, pre-construction forecasts should be used as the project baseline for ongoing carbon reporting and progress tracking throughout the project.

-

For the technical design and construction phases, the pre-construction forecasts should be used to evaluate the evolving design, and the at-tender forecasts should be used to evaluate tenders.

-

For the post-completion phase, the post-completion assessment should be used to check the carbon reductions predicted in the pre-construction and at-tender forecasts have been achieved.

Therefore, by understanding the complete carbon journey of a building, professionals in the built environment can make more informed decisions that benefit both the planet and their organisational motivations. With organisations like RICS setting the bar, the future looks promising for those keen to make a tangible difference in the fight against climate change through WLCAs.

Resources:

- Covering Embodied Carbon: what is it? (Preoptima)

- Climate Emergency Retrofit Guide (LETI)

- Defining and Aligning: Whole Life Carbon & Embodied Carbon (LETI)

- Emissions Gap Report 2022 (UN Environment Programme)

- BS EN 15978:2011

- RICS Professional Statement, Whole Life Carbon Assessment for the Built Environment, 1st Edition

- RICS Consultation 2023

We'd love to hear from you!