Covering Embodied Carbon Series

Embodied carbon - what's all the fuss about?

Read Time 5 mins | Written by: Alex Bantock

Imagine being told that 6.5 years was all you had...

What would you do? Sit around and try to forget about it while time flies by, or would you stand up and make sure it was the best and most productive 6.5 years of your life?

Well, that’s all we have to make a lasting impact on the future of our planet. The clock is ticking, and every decision we make today can determine the course of our battle against climate change. In this critical time, we're zoning in on embodied carbon and how the choices we make during the early design stage can help us reduce a building’s carbon footprint, ensuring a more sustainable built environment.

So here they are, the much-anticipated reasons for all the fuss!

Join our weekly newsletter to get more content like this straight in your inbox!

A Ticking Time Bomb

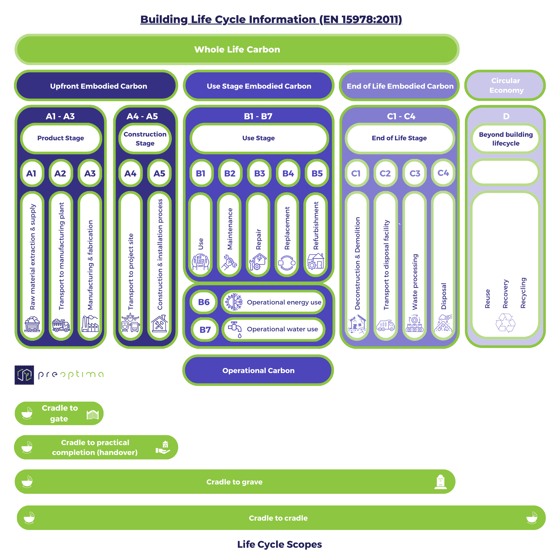

Embodied carbon refers to the carbon emissions generated during the production, transportation, and assembly of building materials, as well as the construction process itself (well this is the ‘upfront embodied carbon’ if we’re being exact). It's a hidden culprit, often overshadowed by its counterpart - operational carbon. But here's the catch: by 2050, embodied carbon could account for almost 50% of the overall carbon emissions from new construction. This means the next 6.5 years are crucial and we need to bring embodied carbon up front and centre (literally)!

Let's focus on the 'Now'

Our focus on operational emissions could be attributed to how much easier it is to measure using occupant energy bills and the carbon intensity of the grid. After all, what gets measured, gets managed! But focusing on operational emissions savings comes at the expense of our carbon budget. Why? Because we’re being sidetracked by using “energy efficiency”, “electrification”, and “insulation” as solutions to meet global climate goals, and whilst these are indeed important, our siloed view means that we are not considering the embodied carbon incurred to achieve that energy efficiency through extra insulation or double/triple glazing for example. So we're burning through our carbon budget on embodied emissions released today to have operational energy savings in the future.

When should we act?

Before the ink is dry on your first sketch for a possible future building - that is when you should start to think about the building's embodied carbon and possibly even before. The earliest design decisions dictate the range for the embodied carbon of the building. If you want to make significant inroads into reducing it, you need to act at the start of the building design process when your capacity from embodied carbon reduction (or avoidance) is at its greatest.

The choice of materials, structural systems, and even the building's shape and orientation can have a massive impact on its carbon footprint. For example, using locally sourced, low-carbon materials can significantly reduce transportation-related emissions, while an optimised building shape can minimise the amount of materials needed. By making informed choices at the onset, your potential for carbon avoidance is maximised!

The realisation of how short the time frame in a building project's lifecycle is in which we can influence the embodied carbon should hopefully spur designers, architects, developers and clients into action as early as possible.

Bringing it all together - whole life carbon

To paint a comprehensive picture of a building's impact, we need to take a whole life carbon (WLC) approach - that’s considering both operational and embodied emissions from now until the building’s end of life.

The data from a WLC assessment can be used for entire lifecycle decarbonisation, ensuring that the guesswork is taken out of actions and everything we do from design choices in the early design stages to retrofitting and demolishing our buildings is well-informed with good carbon insight.

A good WLC assessment is essential to ensure that you have a true reflection of your building's carbon impact and that your design decisions and downstream actions are targeted and meaningful.

Data is of course at the epicentre and that data primarily comes in two forms: 1) Carbon data (the carbon impact associated with materials) and 2) Material quantities (the amount of each material type you will need for your building). A lot of companies are doing amazing work on carbon data (one above all is EC3 and its great API by Building Transparency) but we need accurate material quantities that allow the calculation of the carbon impact of a building to be a true reflection of its as-built self. Without this, we cannot have a reliable estimate of a building's impact, our design decisions are misdirected, outcomes are inconsequential and meaningful carbon reduction is jeopardised.

Preoptima's Carbon Twins give you this missing link by providing you with the most accurate material quantities from the earliest design stages and throughout, whilst using the most transparent freely available data. Our Web App and API give you numbers that you can trust, from an extensive bill of quantities to a full WLC assessment, all in real-time and seamlessly integrated into your current workflows.

We'd love to hear from you!